When it comes to fiber optic technology, standard products can only go so far to meet the needs of engineers and designers who typically require specific lengths or configurations not offered by off-the-shelf fiber optics.

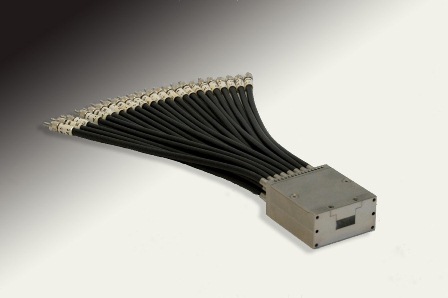

Standard fiber optic products can be formed into a ring, a line, a bundle or even a multi-legged bundle. These do the job if a designer doesn’t know very much about the technology or if a design already has a specific size that will fit a mold. Oftentimes, engineers use standard products as a launching point to see what’s feasible; this helps frame the groundwork for a discussion regarding a more technical or custom part.

For custom designs, much of the work begins at the brainstorming phase, mostly because designers can’t or don’t think of everything that goes along with developing specific fiber optic products. This time investment is important because it not only gives designers a better understanding about what they are asking for, but it also allows the developer to best understand the application, and to hash out solutions to problems the customer hasn’t even thought of.

Typically, custom work in fiber optics begins with submitting a sketch or drawing of what is needed including tolerance of mechanical parts, optical properties, numerical aperture, fiber type, output configuration, and required length. This information frames a basic configuration for the custom design.

Then a fiber optic developer, such as Fiberoptics Technology Inc., begins a dialog to determine or confirm whether or not the provided design characteristics will fit the needs of the application.

While suppliers want to honor and accomplish all of the requests they are given, customer engineers often have an idea they think is feasible and will reach out to see if the idea can work, or if they are unintentionally violating the laws of physics.

Fiberoptics Technology believes the role of the developer goes beyond designing… and includes the effort to confirm the design will work for the intended purpose. Without this time investment and consultation effort, a design could be created that matches the customer’s drawing, but … does not suit the intended purpose.

Finally, even if a design is lucid, complete, and functional, it may not be cost-efficient. Fiberoptics Technology’s consultative style includes a sharp focus on cost, helping customers produce efficient, cost-effective components optimized for performance. This strategy is not solely for the customer’s benefit; it makes little sense to work on a project with slim chances for commercial success… here is where the customer and fiber optic supplier are tied closely together… the customer must be successful before the fiber optic manufacturer can be successful.

This resulting effort and time investment establishes a bond of trust which naturally forms a partnership. Most often, if the customer is successful marketing his product, the mutually beneficial relationship between customer and fiber optic developer can last for decades.