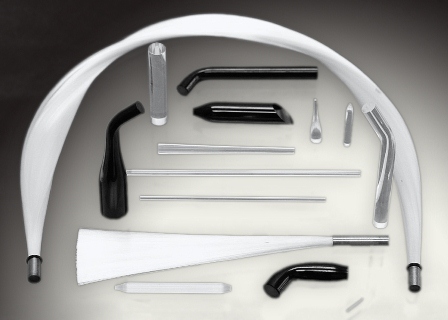

FTI has extensive machining and glass forming equipment to manufacture a wide variety of optical rod and specialty fiber optic taper products ideal for dental and industrial curing applications.

When single optical rods or “Multi element” rods are tapered, the resulting optical characteristic of the rod changes, maintaining the NA of the normal end, while increasing the light gathering ability at the tapered end. The amount of change is a ratio of the diameters. If a .25″ diameter rod has an NA of .5, and the rod is tapered to .125″ diameter, the NA change is 50% (.125/.250) at the small end, making the new NA 1.

Therefore, when light enters the small end of a fiber optics taper, the emerging beam at the other end is somewhat collimated, when compared to the original range of entry angles.

Fiber Optic Taper Applications

Fiber Optic Tapers are used in myriad of applications including dental and industrial curing applications. For dental applications, photocurable materials such as adhesives, sealants and filling material can be quickly cured. This is achieved using a fiber optic light and curing “Tip” that produces a beam of highly concentrated light. Technically speaking, it’s radiant energy in a specific spectral range, long-wave ultraviolet or blue spectrum, depending on the material being cured. The taper plays a critical role in the process, as it tends to concentrate the light at the guide’s distal end. To be effective, the tip is placed very close the to the medium being cured.

Fiber optic tapers are sometimes used in imaging applications where images need to be either magnified or reduced in scale.

The main Medical application is used in a fiberscope; the fiber optic taper serves to increase the NA of the illumination fiber to better match the NA of the scope fiber, which is designed to emit in a wide pattern.